HH PRECSION CASTING addresses difficulties from design concept to production and packaging. Our customers appreciate our ability to translate complicated design demands into reality.

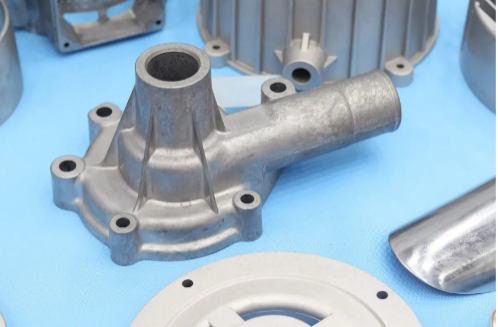

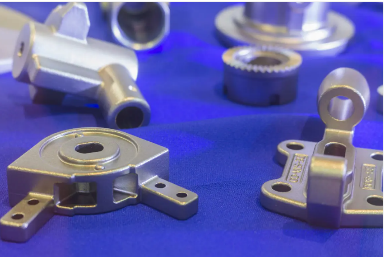

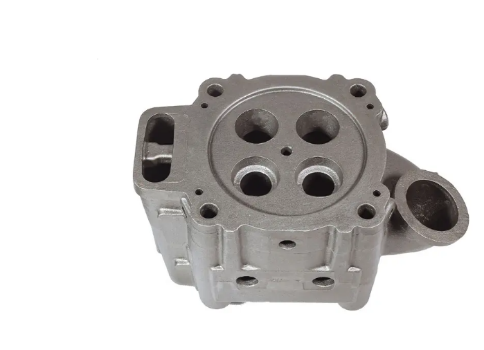

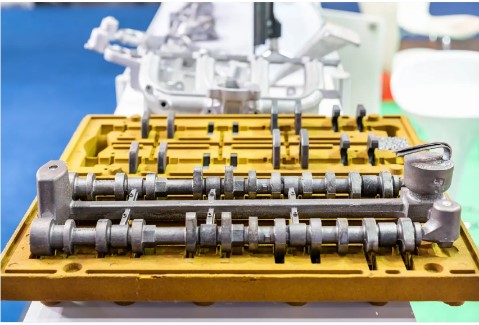

From mould design and testing through precision aluminium part manufacturing, finishing, and packing, HH PRECISION CASTING handles all elements of aluminium die cast manufacturing.

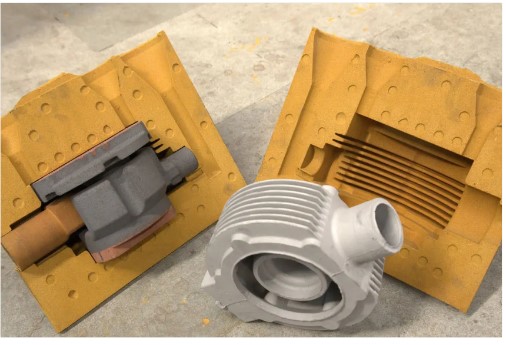

Shell Mould Casting is a precision casting process known for producing high-accuracy, smooth-surface, and dimensionally consistent metal components. Using a heated metal pattern and a special sand-resin mixture, this method creates thin, high-strength shells that form the mould, resulting in exceptional detail and uniformity.

Reliable, consistent, and versatile, Shell Mould Casting is a preferred choice for manufacturers seeking precision and performance in every component.